DIY pcb making - my first board

After getting back into electronics recently, I decided to have a go at making a PCB. A friend pointed me to Pulsar Pro FX, a special toner release paper.

I learned a few things along the way:

- use thin board, this makes a huge difference. I found 0.0032" board at Crownhill in the UK, which seems perfect

- let the laminator warm up enough, wait at least 15 minutes after the light comes on

- always leave enough of an edge on the paper and board, excess can always be trimmed off later

Failing to do these wastes time, paper and energy and results in lots of cleaning up to do.

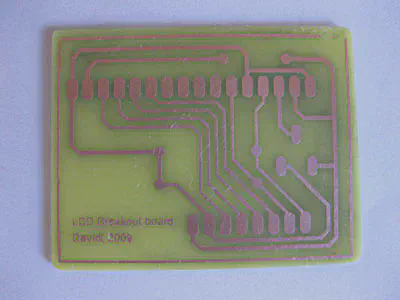

Below is a sample of what the finished PCB looks like. The slight roughness round the edges is due to cutting it with scissors and the black tint is because I did not have acetone to clean the toner off with.

There is an excellent guide to using the paper which includes step-by-step pictures and the finished result. SMD and double sided boards are perfectly possible, but I haven’t tried yet.